SilverGuard™ Antimicrobial-coated Ductwork

Your customers realize that harmful bacteria can contaminate their HVAC and ventilation systems, threatening the health and safety of everyone in the building. However, potential contamination from destructive microbes is not limited to terrorist attacks, it is a day-to-day concern.

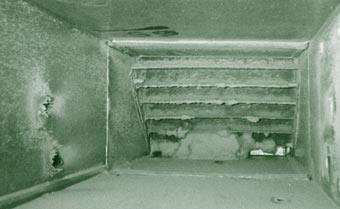

Outdoor pollution levels have improved over the past 20 years, but many schools, hospitals, day-care centers, aquatic facilities, and offices have become much tighter buildings with minimal fresh air flow. These buildings retain pollutants at greater levels. If maintenance of the HVAC system is haphazard and moisture is present, bacteria, mold, mildew, and other fungi can thrive.

Most of the 300,000 known types of mold are harmless, but scientists are concerned about the potential dangers of exposure to molds that can produce mycotoxins, natural compounds that can cause serious respiratory problems.

In response to the rise in asthma and allergies among schoolchildren today, the U.S. EPA has issued new air quality standards to provide additional protection for children and asthmatics. The governor of California has also signed a bill creating the Toxic Mold Protection Act, which sets the toughest toxic mold standards in the nation.

With a focus on HVAC systems, members of ASHRAE are studying retrofit programs to improve health and safety in existing buildings, and design features that could be incorporated into new buildings to improve health and safety.

You Have a Revolutionary New Safeguard

The first line of defense against destructive microbes is a clean and well-maintained HVAC system with good air distribution.

McGill AirFlow's SilverGuard ductwork is a second line of defense in the battle for good indoor air quality (IAQ). SilverGuard antimicrobial ductwork inhibits the growth of bacteria, mold, mildew and other fungi on its coated surfaces. SilverGuard ductwork is the perfect solution for applications where indoor air quality is an issue, such as food preparation facilities, hospitals, day-care centers, nursing homes, and schools. It is ideal for both consumer and industrial installations — anywhere bacteria, mold, and mildew grow.

The Natural Protection of Silver

Although several organic post-coating systems on today's market offer antimicrobial protection, only SilverGuard™ antimicrobial-coated ductwork from McGill AirFlow offers the natural protection of silver. SilverGuard was the first such product available in the U.S.

Here's how it works

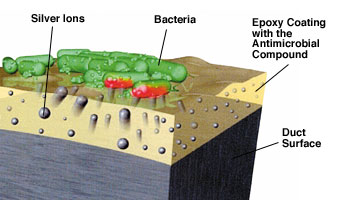

The small amount of moisture present on a table top at ambient conditions is all the moisture needed for microbes to grow — and to cause the antimicrobial compound to begin its work. The zeolite matrix acts as an ion pump, exchanging silver ions with other ions present in moisture. The silver ions penetrate the microbe membrane and prevent RNA/DNA splitting, thereby preventing growth. The ion exchange continues until it reaches a state of equilibrium and does not release additional silver ions until there is a change in the amount of moisture present.

Safe and Effective

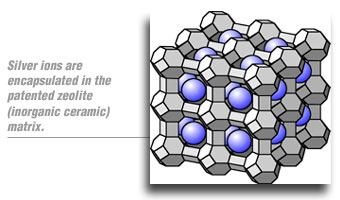

To fabricate SilverGuard™ ductwork, McGill AirFlow uses coil steel coated with an epoxy that includes the antimicrobial compound. The antimicrobial compound is a patented zeolite (inorganic ceramic) matrix that encapsulates millions of silver ions. This technology is safe and has been proven to be successful in controlling the spread and growth of many types of bacteria, mold, mildew and other fungi.

Tested and Registered

SilverGuard™ duct systems are available with antimicrobial-coated steel. The antimicrobial compound is EPA registered (No. 71277-1-72854). The epoxy coating was tested in accordance with UL 723 and found to have NFPA 90A/90B FS/SD ratings of less than 25/50.

Long-lasting, Durable Protection

Both the interior and exterior of the steel ductwork are coated by an epoxy film bonded to the metal surface by heat. This clear epoxy coating applied to the outer surface offers additional corrosion protection and a cleanable and paintable surface. Although the antimicrobial compound is only on the interior surface of the SilverGuard™ ductwork, antimicrobial coating of other surfaces can be specified. A translucent blue pigment is added to the coating to indicate what surface is antimicrobial.

The controlled release of silver ions by the antimicrobial coating offers long-lasting, durable protection. For most types of microorganisms, the antimicrobial-treated surfaces will be virtually free of microbial growth in three to four hours — and the antimicrobial benefit lasts as long as the coating remains on the steel.

Easy to Clean and Maintain

Cleaning and maintaining the surface of an antimicrobial-coated product is easy — just apply a mild detergent with a soft sponge or cloth, rinse, then let air dry. There's no need for abrasives. They should be avoided to prevent coating damage. But a small scratch on the coating won't affect the product's efficacy. The silver ions will diffuse and migrate to the bacteria or microbes within the scratch as the active silver bridges the gap. The silver ions can bridge up to a 1/4-inch gap. Any repairs and touch-ups are easily made using SilverGuard epoxy paint.

Welded Joints? - No Problem!

Coatings applied to both galvanized and stainless steels have been formulated to allow the metal to be pressed, drawn, bent, roll formed and otherwise fabricated into parts, without the loss of the coating or reduction in efficacy.

Both spot-welded and fully welded joints are possible without the need to remove the epoxy coating. Small scratches or weld burns through the epoxy coating will not impact efficacy, since the silver ions still diffuse and migrate within the scratch.

Product Availability

SilverGuard™ is available in all of McGill AirFlow's duct and fitting types and constructions, including round, flat oval, and rectangular, single-wall, single-wall lined, and double-wall lined duct and fittings.

Standard materials are G-60 galvanized steel and S304 stainless steel. All duct and fittings will have metal thicknesses and reinforcements in conformance with the 1995 SMACNA HVAC Duct Construction Standards, as prescribed in McGill AirFlow's individual dimension booklets for specific duct types.

Questions and Answers

- What is SilverGuard ductwork?

- SilverGuard ductwork was developed as a second line of defense in the fight against bacteria, mold, mildew and other fungi residing in HVAC duct systems. To fabricate SilverGuard ductwork McGill AirFlow uses coil steel pre-coated with an epoxy that includes the antimicrobial compound.

- What is the antimicrobial compound?

- The antimicrobial compound is a patented zeolite that encapsulates millions of silver ions. Silver, a natural protective element, has been used for over 6,000 years for food and beverage storage. This proven technology is successful in controlling growth of bacteria, mold, mildew and other fungi.

- How does the antimicrobial compound work?

- Moisture is the trigger. As little moisture as is present on a table top at ambient conditions is all that is needed for microbes to grow and to cause the antimicrobial compound to work. The zeolite acts as an ion pump exchanging silver ions with other ions (Na+, Ca+, etc.) present in moisture. The ion exchange continues until it reaches a state of equilibrium. The silver ions penetrate the microbe membrane and prevent RNA/DNA splitting, thereby inhibiting growth.

- Where might SilverGuard ductwork be used?

- SilverGuard ductwork is recommended for applications where growth of bacteria, mold, mildew and other fungi are a concern and operating temperatures do not exceed 300°F.

- What type of coating is on the SilverGuard ductwork?

- The antimicrobial compound is incorporated into an epoxy coating which is bonded to the metal surface by heat. Translucent blue pigment is added to the epoxy coating to indicate to what surfaces the compound is applied.

- What surfaces of the SilverGuard ductwork are coated?

- Both the interior and exterior of the steel ductwork are coated. A clear epoxy coating is applied to the outer surface that offers additional corrosion protection and a more cleanable and paintable surface. Only the coating on the interior surface of the ductwork contains the antimicrobial compound, unless otherwise specified.

- Is it necessary to clean SilverGuard ductwork?

- Yes, treated articles must still be cleaned to ensure that the surfaces will be free of a build-up of destructive microbes. It is best to view the SilverGuard ductwork as a second line of defense in the fight against bacteria, mold, mildew and fungus in duct systems.

- How is the coated steel surface cleaned?

- The surface of the SilverGuard ductwork may be cleaned with a mild detergent and a soft sponge or cloth, and then air-dried or dried with a soft cloth. Harsh abrasive cleaners must be avoided in order to prevent damage to the epoxy coating.

- How abrasion resistant is the epoxy coating?

- The abrasion resistance of the epoxy coating is similar to that of countertop plastic laminates.

- If the coating is scratched, will the surface of SilverGuard ductwork still be protected?

- Small scratches or weld burns through the epoxy coating will not adversely impact product efficacy. The silver ions contained within the ceramic matrix can still diffuse and migrate to the microbes within the scratch. The active silver ions can "bridge" up to a 1/4-inch gap. Numerous or wide scratch patterns will reduce the efficacy of the product. Contact the McGill AirFlow sales engineering office nearest you to order SilverGuard ductwork epoxy paint for touch-ups.

- Won't the epoxy coating separate from the steel when it is formed?

- No. Coatings applied to both galvanized and stainless steels have been formulated to allow the metal to be pressed, drawn, bent, roll formed and otherwise fabricated into parts, without loss of the coating or significant effect on the efficacy of the product.

- Can SilverGuard ductwork be welded and repaired?

- Yes, both spot welded and fully welded joints are possible without the need to remove the epoxy coating. Repairs are easily made using the SilverGuard ductwork epoxy paint.

- How long will the antimicrobial compound last?

- The durability of the antimicrobial compound will be determined by the environment. Salt spray, water soak and humidity testing has indicated that the antimicrobial benefit will be present as long as the epoxy coating remains on the steel. However, abrasive conditions that cause wear of the epoxy coating will reduce the period of effectiveness.

- How do I know that the antimicrobial compound is still inhibiting the growth of microbes?

- Controlled laboratory and in-field swab procedures have been developed to show that the antimicrobial compound is still inhibiting the growth of microbes on the interior surfaces of the ductwork. Contact the McGill AirFlow sales engineering office nearest you for more information.

- Is anyone using the antimicrobial compound today?

- Yes, the antimicrobial compound has been used in Japan for about eight years in paints, flooring, kitchenware and various other consumer products. In the United States, this antimicrobial product is being used in footwear, water bottles, clothing and medical applications. Steel coils with an epoxy coating incorporating the antimicrobial compound are now available. SilverGuard antimicrobial pre-coated steel ductwork from McGill AirFlow is the first such product available in the U.S.

- Does the coating on SilverGuard ductwork meet any government or independent standards?

- Yes, the antimicrobial compound is EPA registered (No. 71277-1-72854), and the epoxy coating was tested in accordance with UL 723 and found to have NFPA 90A/90B FS/SD ratings of less than 25/50.

- Do competitive products exist for SilverGuard ductwork?

- Yes. There are several organic post-coating systems available on the market that offer antimicrobial protection. However, the antimicrobial technology is the only one offering the natural protection of silver.

- How do I get the SilverGuard ductwork?

- McGill AirFlow offers SilverGuard ductwork through all its sales engineering offices nationwide. Please contact the McGill AirFlow sales engineering office nearest you for more information.