Uni-Stack™ — U.L. Listed Chimney, Breeching, and Grease Duct Systems

Uni-Stack ductwork is designed for use as prefabricated chimney, breeching, and exhaust systems. We can provide all the components needed to construct a complete system, including round duct, elbows, tees, supports, terminations, and connecting devices. Our standard designs meet the requirements of a wide range of boilers, incinerators, heating appliances, and industrial processes. Because corrosion can be a major problem in stacks, each of our standard products is designed to resist specific corrosive conditions. Components and materials should be chosen based on their ability to stand up to the corrosive properties of the flue gas being vented.

Our engineers can size your system and recommend one of our standard products or custom design a chimney system for you. By providing corrosion and thermal analyses for metals, refractories, and other chimney materials, we can determine how they will be affected by specific flue gas components. We can also make mid-flue and surface temperature calculations, seismic calculations, and structural analyses to help meet the requirements of your application.

Uni-Stack™-S

Single-Wall Stainless Steel Ductwork

Uni-Stack-S single-wall, stainless steel ductwork is designed to resist atmospheric corrosion in exhaust systems that vent fume hoods and heating appliances and for boiler breeching systems. It can be used with fuels such as liquid propane gas, natural gas, #2, #4*, #5*, and #6* fuel oils, wood*, and coal* (*316 stainless steel should be specified when using these fuels for combustion). It is suitable for caustic air and fumes, vapors, and particle-containment systems. Uni-Stack-S ductwork can handle flue gas with a maximum temperature of 1,400°F for continuous firing and a maximum temperature of 1,800°F for intermittent firing.

Construction

Uni-Stack-S single-wall duct is constructed with a welded longitudinal seam in standard lengths of 18, 30, and 42 inches. Standard diameters are 6 to 48 inches in 2-inch increments. For diameters of 6 to 36 inches, the standard material is 20-gauge, 304 stainless steel. For diameters of 38 to 48 inches, the standard material is 18-gauge, 304 stainless steel. Other diameters and materials are available. All components have flanged ends. Vee bands and sealant are provided to secure the flanged connections.

Clearance Requirements

Consult local codes to determine how much clearance is needed between Uni-Stack-S ductwork and combustible building materials such as wood and plasterboard.

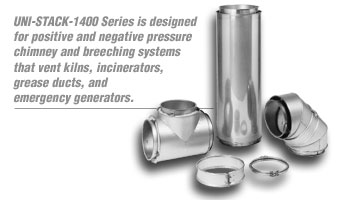

Uni-Stack™-1400 Series

Double-Wall Ductwork

Uni-Stack-1400 double-wall ductwork is designed for positive and negative pressure chimney and breeching systems that vent boilers, kilns, incinerators, grease ducts, and emergency generators. The double-wall design features a stainless steel inner liner and aluminized steel outer shell. It helps maintain a high flue gas temperature so that corrosive gases will not condense inside the stack. Insulation is available to lower the temperature of the duct's outer shell. This duct can be used with fuels such as liquid propane gas, natural gas, #2, #4*, #5*, and #6* fuel oils, wood*, and coal* (*316 stainless steel should be specified when using these fuels for combustion). It is suitable for caustic air and fumes, grease vapors, and particle-containment systems. Uni-Stack-1400 ductwork can handle flue gas with a maximum temperature range of 1,000°F to 1,400°F for continuous firing and a maximum temperature range of 1,400°F to 1,800°F (2,000°F in grease duct applications) for intermittent firing.

Construction

| Uni-Stack-1400 double-wall ductwork is available in five standard models: | |

|---|---|

| Model 1400 | has a 1-inch air space between the outer shell and liner. |

| Model 1401 | has 1 inch of fiber insulation between the outer shell and liner. |

| Model 1402 | has 2 inches of fiber insulation between the outer shell and liner. |

| Model 1403 | has 3 inches of fiber insulation between the outer shell and liner. |

| Model 1404 | has 4 inches of fiber insulation between the outer shell and liner. |

Uni-Stack-1400 duct is constructed with a welded longitudinal seam in lengths of 18, 30, and 42 inches. Standard diameters are 6 to 48 inches in 2-inch increments. For diameters of 6 to 36 inches, the standard material is 20-gauge, 304 stainless steel for the liner and 24-gauge aluminized steel for the outer shell. For diameters of 38 to 48 inches, the standard material is 18-gauge, 304 stainless steel for the liner and 20-gauge aluminized steel for the outer shell. The duct is also available in other diameters and with 316 stainless steel liners or outer shells. Liners have van-stoned ends. Vee bands and sealant are provided to secure the flanged connection. Outer shells are joined by draw bands for environmental protection. To maintain the concentric spacing between the inner liner and outer shell, spacer clips are welded to the liner and hooked over the edges of the shell.

Clearance Requirements

For noncombustible materials, Model 1400 (1,000°F applications) requires a clearance of 2 inches when inside diameters are 18 inches or less, and a clearance of 4 inches when inside diameters are greater than 18 inches. For Model 1400 (1,400°F applications), the clearance is the same as for combustible materials. For Models 1401, 2, 3, 4 (1,400°F applications), a clearance of 4 inches from noncombustible materials is required when the inside diameter is 18 inches or greater.

| The following clearances must be maintained from combustible building materials. | ||

|---|---|---|

| Model 1400 | 4 inches for 1,000°F applications, 6 inches for 1,400°F applications. | |

| Models 1401, 2, 3, 4 | 2 inches for 1,000°F applications, 4 inches for 1,400°F applications. | |

|

Models 1401, 2, 3, 4 (grease duct applications) |

Inside Diameter (inches) | Clearance (inches) |

| 6-8 | 10 | |

| 10 | 12 | |

| 12 | 13 | |

| 14 | 14 | |

| 16 | 15 | |

| 18 | 16 | |

| 20-22 | 17 | |

| 24-36 | 18 | |

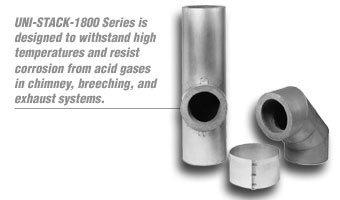

Uni-Stack™-1800 Series

Refractory-Lined Steel Ductwork

Uni-Stack-1800 refractory-lined, steel ductwork is designed to withstand high temperatures and resist corrosion from acid gases in chimney, breeching, and exhaust systems that vent boilers, furnaces, incinerators, fireplaces, appliances that burn wood or coal, kilns, kitchen appliances, diesel/gas engines, heat recovery systems, and process equipment. It can be used with all types of fuels and combustible materials. Uni-Stack-1800 ductwork can handle flue gas with a maximum temperature range of 960°F to 3,100°F for continuous firing and intermittent firing.

Construction

| Uni-Stack-1800 ductwork is available in eight refractory-lined models: | |

|---|---|

| Model 1800 | has a refractory aggregate bonded with calcium aluminate cement. |

| Model 1800 Plus | replaces 1 inch of 1800 refractory with insulating board for thermal control in heat recovery applications. |

| Model 1800 V | has a refractory of high-density aggregate bonded with high-purity calcium aluminate cement. |

| Model 1800 AR-2 | has a refractory of high-density aggregate co-bonded with high-purity calcium aluminate cement and potassium silicate binders. |

| Model 1800 AR-H | has a refractory that is a low-shrink mix of 60 percent alumina to provide high strength, high density, and high abrasion resistance. |

| Model 1800 AR-T | has an amorphous, vitreous silica refractory to provide high density and high abrasion resistance. |

| Model 1800 BB | has foamed, closed-cell borosilicate blocks secured to the outer shell with 1/8-inch urethane asphalt adhesive membrane. |

| Model 1800 EE | uses 1 inch of the standard Model 1800 refractory for engine exhaust applications. |

| Model 1800 CUS | can be supplied with custom refractory and membrane linings to meet your needs. |

Uni-Stack-1800 duct is constructed with a welded (or riveted for 26 gauge) longitudinal seam in standard lengths of 36 inches for inside diameters of 4 through 8 inches, and lengths of 48 inches (72 inches for heavy gauges) for inside diameters of 9 through 60 inches. Standard diameters are 4 to 60 inches inside diameter (Model 1800 Plus is 4 to 60 inches and Model 1800 BB is 30 inches or greater). Standard outer shell materials are 26-gauge aluminized steel or 11-gauge galvanized steel. Stainless steel (304 and 316) jackets are available. Model 1800 is not available in 26 gauge for inside diameters greater than 36 inches. Components are joined with a leak-proof and acid-resistant sealant. An 8-inch-wide, 26-gauge aluminized steel draw band is placed over each sealed joint and bolted tightly to secure the joint. For heavy-gauge outer shells, an 11-gauge galvanized steel draw band is available. Joints can also be welded to increase strength.

Clearance Requirements

For noncombustible materials, a clearance of 2 inches is required for inside diameters of 4 to 18 inches, and a clearance of 4 inches is required for inside diameters greater than 18 inches. Note: clearances in a noncombustible interior chase shall be as necessary to ease installation and/or allow access.

The following clearances must be maintained between Model 1800 and combustible building materials (a clearance of 6 inches is required for all diameters when used with low-heat appliances producing flue gas temperatures of 1,000°F or less).

|

Inside Diameter (inches) |

Clearance (inches) |

|---|---|

| 1-15 | 16 |

| 18-21 | 18 |

| 24 | 20 |

| 27 | 21 |

| 30-36 | 22 |

| 39-42 | 25 |

| 45 | 26 |

| 48 | 27 |

| 51 | 28 |

| 54 | 29 |

| 57 | 30 |

| 60 | 31 |

Application References and Listings: UL (Model 1800 only), BOCA, NFPA, SBC, UBC, NBC, ICBO

Uni-Stack™-ENG

Engineered Chimneys

In addition to supplying our standard products, we can engineer a chimney for your application. Our engineering services include sizing, structural analysis, thermal analysis, and corrosion analysis. We can recommend a stack lining for specific thermal and corrosion conditions. Typical linings are cast refractory, gunned refractory, foamed borosilicate block, fiberglass-reinforced polymer, and organic coatings.

We can also design a single stack that contains multiple chimney systems constructed of steel or other materials. For existing chimneys, we can perform field inspections and recommend repairs. Large projects can be field fabricated and installed at the jobsite.

The chart below lists the most common applications for each of our standard products. In addition, we can provide effective, economical solutions for unique venting and exhaust applications.

*HWH (Hot Water Heater)

- Boiler-HWH*-Furnace, Gas, Negative Pressure, Noncondensing

-

Uni-Stack-S

Uni-Stack-1400, 1, 2, 3, 4, -304

Uni-Stack-1800

Uni-Stack-1800 Plus

Uni-Stack-1800 with membrane

Uni-Stack-ENG

- Boiler-HWH*-Furnace, Gas, Positive Pressure, Noncondensing

-

Uni-Stack-S

Uni-Stack-1400, 1, 2, 3, 4, -304

Uni-Stack-1800

Uni-Stack-1800 Plus

Uni-Stack-1800 with membrane

Uni-Stack-ENG

- Condensing Boiler-HWH*-Furnace-Unit Heater, Gas, Negative Pressure

-

Uni-Stack-1800 with membrane

Uni-Stack-1800 AR-T

Uni-Stack-ENG

- Condensing Boiler-HWH*-Furnace-Unit Heater, Gas, Positive Pressure

-

Uni-Stack-1800 with membrane

Uni-Stack-1800 AR-T

Uni-Stack-ENG

- Boiler-HWH*-Furnace, #1 and #2 Oil

-

Uni-Stack-1400, 1, 2, 3, 4, -316

Uni-Stack-1800

Uni-Stack-ENG

- Boiler-HWH*-Furnace, #3 and #6 Oil

-

Uni-Stack-1400, 1, 2, 3, 4, -316

Uni-Stack-1800

Uni-Stack-ENG

- Boiler-HWH*-Furnace, Coal

-

Uni-Stack-1400, 1, 2, 3, 4, -316

Uni-Stack-1800

Uni-Stack-ENG

- Boiler-HWH*-Furnace, Wood

-

Uni-Stack-1400, 1, 2, 3, 4, -316

Uni-Stack-1800

Uni-Stack-ENG

- Engine Exhaust, Diesel

-

Uni-Stack-1400, 1, 2, 3, 4, -304

Uni-Stack-1800

Uni-Stack-1800 Plus

Uni-Stack-1800 EE

Uni-Stack-ENG

- Engine Exhaust, Gas Turbine

-

Uni-Stack-1400, 1, 2, 3, 4, -304

Uni-Stack-1800

Uni-Stack-1800 Plus

Uni-Stack-1800 EE

Uni-Stack-ENG

- Incinerator, Wood and Paper Products <1,400°F

-

Uni-Stack-1800

Uni-Stack-1800 Plus

Uni-Stack-ENG

- Incinerator, Wood and Paper Products >1,400°F

-

Uni-Stack-1800

Uni-Stack-1800 Plus

Uni-Stack-1800 AR-T

Uni-Stack-ENG

- Incinerator, General Hospital Waste

-

Uni-Stack-1800 V

Uni-Stack-1800 AR-2

Uni-Stack-1800 AR-T

Uni-Stack-ENG

- Incinerator, Pathological

-

Uni-Stack-1800 V

Uni-Stack-1800 AR-2

Uni-Stack-1800 AR-H

Uni-Stack-1800 AR-T

Uni-Stack-ENG

- Incinerator, Special Conditions

- Uni-Stack-ENG

- Hood, Kitchen Exhaust

-

Uni-Stack-1400, 1, 2, 3, 4, -304

Uni-Stack-1400, 1, 2, 3, 4, -316

Uni-Stack-1800

Uni-Stack-1800 Plus

Uni-Stack-ENG

- Hood, Laboratory Exhaust

-

Uni-Stack-S

Uni-Stack-ENG

- Hood, Fume

-

Uni-Stack-S

Uni-Stack-ENG

- Scrubber, Inlet Side

-

Uni-Stack-1800 V

Uni-Stack-ENG

- Scrubber, Outlet Side

-

Uni-Stack-1800 BB

Uni-Stack-ENG

- Heat Recovery, Inlet Side

-

Uni-Stack-1800 V

Uni-Stack-ENG

- Heat Recovery, Outlet Side

-

Uni-Stack-1800 AR-T

Uni-Stack-1800 BB

Uni-Stack-ENG